Climbing webbing is an essential component in the climber’s toolkit, providing crucial support and versatility where ropes alone aren’t enough. This unassuming material plays a vital role in ensuring safety during vertical adventures.

Climbing webbing is a flat, strong, flexible synthetic material used in climbing and mountaineering. Made primarily from nylon or polyester in either tubular or flat forms, it has a strength capacity of 2,000-4,000 pounds. Climbers rely on webbing for anchor building, slings, rescue operations, and gear organization.

Discover the types of climbing webbing, their applications, and how to select the right option for your climbing needs – knowledge that benefits both novice and seasoned climbers.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

Climbing webbing is a flat, strong synthetic textile material woven into either tubular or flat strips, designed specifically for rock climbing and mountaineering. Unlike rope, webbing has a ribbon-like structure that distributes force across a wider area, making it ideal for creating anchors, slings, and other climbing systems.

The defining characteristics of climbing webbing include:

This fundamental climbing tool plays a crucial role in climbing safety systems, providing versatility that specialized hardware cannot match. Its design allows it to be easily tied, cut to custom lengths, and configured for various purposes in the vertical environment.

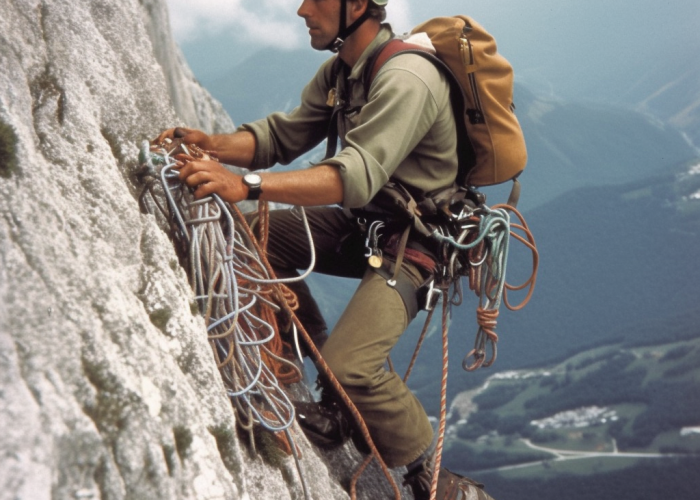

Climbing webbing serves four main purposes in climbing and mountaineering: anchor building, creating slings and runners, performing rescue operations, and organizing gear. Its versatility allows climbers to adapt to various situations while maintaining safety and efficiency in vertical environments.

The primary applications of climbing webbing include:

Climbing webbing’s flat design and high strength make it an essential component in a climber’s toolkit, offering solutions that ropes or specialized hardware alone cannot provide. Its ability to be configured into various forms on demand makes it invaluable for both planned climbing activities and unexpected situations requiring improvisation.

Climbing webbing is primarily made from synthetic materials including nylon, polyester, and Ultra-High Molecular Weight Polyethylene (UHMWPE), with nylon being the most common due to its balanced properties. Each material offers different characteristics in terms of strength, durability, UV resistance, and water absorption.

Nylon is the standard material for most climbing webbing because of its excellent strength-to-weight ratio and good dynamic properties. It provides 15-30% stretch under load, helping absorb impact forces. Nylon webbing is available in both tubular and flat forms, and is relatively affordable. Its main drawback is that it absorbs water and can lose up to 15% strength when wet.

Polyester offers better UV resistance and less elasticity (10-15% stretch) than nylon. It has a higher melting point, making it more resistant to friction-generated heat, and absorbs significantly less water. While generally having slightly lower strength than equivalent nylon webbing, polyester maintains more of its strength when wet, making it suitable for wet environments.

Ultra-High Molecular Weight Polyethylene (UHMWPE), also known as Dyneema or Spectra, is a premium material that’s up to five times stronger than steel by weight. It features minimal stretch (less than 5%), excellent UV resistance, and doesn’t absorb water. However, UHMWPE is significantly more expensive, has poor knot-holding ability, and a relatively low melting point that makes it vulnerable to friction damage.

Other specialized materials include polypropylene, which floats in water and is used in water rescue applications, and Kevlar, which offers excellent heat resistance for specialized uses.

There are two main types of climbing webbing: tubular webbing and flat webbing. Each type has distinct characteristics that make it suitable for different climbing applications and scenarios.

Tubular webbing is constructed as a hollow tube of woven material. It’s typically lighter than flat webbing of equivalent width and offers more flexibility, making it easier to handle, tie, and manipulate. This type generally has better knot-holding ability and is usually more comfortable against the skin. Tubular webbing commonly comes in widths ranging from 9/16″ to 1″ (14mm to 25mm) and is popular for most general climbing applications.

Flat webbing, on the other hand, is a solid, flat strip of material with no hollow center. It’s generally stronger than tubular webbing of the same width and offers more resistance to abrasion and wear. However, it tends to be stiffer and less pliable than tubular webbing, which can make it more challenging to tie knots with. Flat webbing is often used for heavy-duty applications and commonly comes in widths from 1″ to 2″ (25mm to 50mm).

Both types of webbing can be found in various colors, which helps climbers organize their gear and differentiate between pieces of different ages or purposes. The choice between tubular and flat webbing depends largely on the specific climbing scenario, personal preference, and the intended application.

Flat webbing is best used for anchor building, rappel stations, and high-abrasion scenarios, while tubular webbing is ideal for general climbing applications, slings, and situations requiring better handling and knot security. The choice depends on your specific needs for strength, durability, flexibility, and comfort.

Flat webbing should be your choice when:

Tubular webbing performs better when:

The strength-to-weight ratio favors tubular webbing for most recreational climbing, making it the more common choice among climbers. However, in specific situations where durability and absolute strength are paramount, flat webbing remains the preferred option despite its additional weight and reduced flexibility.

Most experienced climbers carry both types in their gear collection, selecting the appropriate webbing based on the specific climbing environment and intended application.

Climbing webbing typically has a strength rating between 2,000 to 4,000 pounds (907-1,814 kg), with exact values depending on material, width, and construction type. This high strength capacity makes it reliable for critical climbing safety applications.

Width directly affects strength—1-inch (25mm) tubular webbing usually rates around 4,000 pounds, while 9/16-inch (14mm) webbing typically handles about 2,500 pounds. Material choice also matters: nylon offers good overall strength with elasticity, polyester performs better when wet, and UHMWPE provides the highest strength-to-weight ratio but at higher cost.

Construction type influences strength as well, with flat webbing generally providing higher absolute strength than tubular webbing of equal width. However, environmental factors like UV exposure, abrasion, and age gradually reduce webbing strength over time, requiring regular replacement for safety-critical uses.

Climbing webbing serves four main purposes: anchor building, creating slings, rescue operations, and gear organization. Its versatility makes it an essential tool for climbers and mountaineers.

For anchor building, webbing creates secure attachment points around trees, rock features, or other natural anchors. Its flat profile distributes force evenly, preventing damage while providing crucial connection points for top-rope setups, rappel stations, or belay anchors.

As slings and runners, webbing extends protection, reduces rope drag, and creates quickdraws. Custom-length slings adapt to specific route requirements, while alpine draws adjust in length to manage rope on wandering routes.

In rescue situations, webbing can fashion emergency harnesses, create load-distributing anchors, and build improvised hauling systems when standard equipment is unavailable.

For gear management, climbers use webbing to make gear slings, bundle equipment for transport, and organize ropes during approaches or descents—all without adding significant weight to their packs.

Climbing webbing stands as a fundamental tool in any climber’s arsenal. Its impressive strength, versatility, and adaptability make it indispensable for anchors, slings, rescue operations, and gear organization. Whether tubular or flat, nylon or specialized material, proper webbing selection enhances safety and efficiency in vertical adventures.

Clean climbing webbing with mild soap and lukewarm water. Gently hand wash without harsh scrubbing, rinse thoroughly, and air dry away from direct sunlight and heat sources. Never use bleach, detergents with brighteners, or washing machines. After cleaning, inspect the webbing carefully for any damage that might have been hidden by dirt before returning it to service.

Most climbing webbing is not waterproof. Nylon webbing can absorb up to 10% of its weight in water and lose 10-15% of its strength when wet. Polyester webbing performs better with less water absorption and strength loss. For water environments, consider Dyneema/Spectra (UHMWPE) webbing, which is highly water-resistant and maintains strength when wet, though it comes at a higher price point.

Climbing webbing typically has a shelf life of 3-5 years with normal use, but should be replaced sooner if visibly damaged, exposed to chemicals, or subjected to excessive UV radiation. Always inspect webbing before each use and retire it if you notice fraying, discoloration, or stiffness. Even unused webbing stored in ideal conditions should be evaluated after 10 years.

Yes, climbers commonly make personal slings by tying webbing into loops using a water knot. However, these homemade slings are significantly weaker than manufactured sewn slings, typically reducing strength by 30-50%. Always tie water knots properly with at least 3 inches (7.5cm) of tail and regularly check them for slippage. For critical applications, commercial sewn slings are recommended.

Replace your climbing webbing if you notice fraying, cuts, abrasions, discoloration, stiffness, or fuzzy texture. Also retire webbing after any significant falls, chemical exposure (including sunscreen), or if it’s been in regular use for more than 2-3 years. When in doubt about webbing condition, the safest approach is to replace it.

Climbing webbing is specifically manufactured to meet stringent safety standards for life support applications, with precisely controlled breaking strengths typically between 2,000-4,000 pounds. Unlike hardware store webbing or decorative straps, climbing webbing undergoes rigorous testing and quality control. Other webbing types (like automotive or crafting webbing) aren’t designed or tested for climbing loads and should never be used in climbing safety systems.