Selecting the right webbing for breathable armbands involves balancing comfort, durability, and device security. With extensive experience manufacturing custom webbing for wearable devices and consumer electronics, material choices directly affect user satisfaction and product performance.

Polyester mesh webbing in 1-1.5 inch widths typically provides the optimal balance of breathability and strength for most armband applications, offering excellent moisture-wicking properties and 800-1,200 lbs breaking strength. However, the ideal choice depends on device weight, wear duration, skin sensitivity, and whether you need elastic stretch or adjustable sizing.

Learn how to choose breathable webbing for armbands—balance comfort, elasticity, and device security with proven specs from real-world manufacturing.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

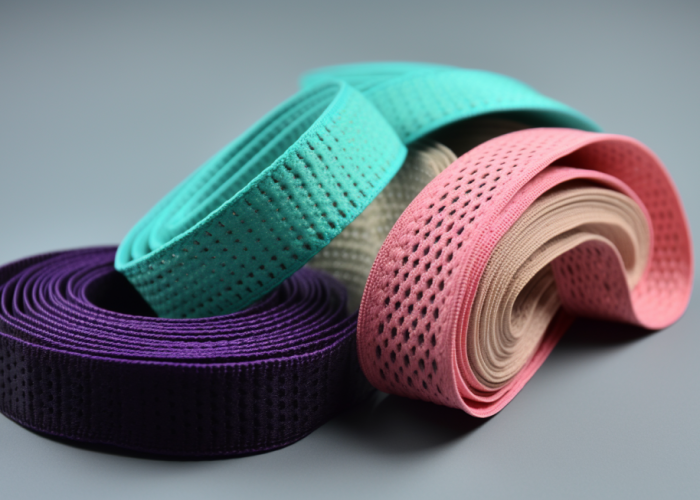

For armband applications, polyester mesh webbing provides the best breathability through its open-weave construction that allows airflow while maintaining structural integrity. Standard polyester webbing offers excellent moisture-wicking properties and quick-dry characteristics, while nylon retains moisture longer against skin. Polypropylene provides good water resistance and cost-effectiveness, but polyester performs better under UV exposure and maintains better shape retention.

Mesh materials allow air to pass through freely due to their open-weave structure, creating air channels that promote ventilation. Polyester is highly water resistant and won’t absorb moisture, which means it maintains its strength and shape even when soaked, plus it’s mildew resistant—a huge advantage for extended-wear applications. However, mesh construction requires reinforced edge finishing during manufacturing to prevent fraying at attachment points.

Material Comparison for Armband Breathability:

Material Airflow Moisture Handling Breaking Strength (1″) UV Performance Best Use Case

Polyester Mesh Excellent Quick-dry, no absorption Lower than solid Excellent (67%+ retention after 12 months) Fitness trackers, all-day wear

Solid Polyester Good Moisture-wicking 1,500-1,800 lbs Excellent (67%+ retention after 12 months) Medical devices, work badges

Polypropylene Good Water-resistant 600-900 lbs Poor (70% loss in 6 days without UV treatment) Budget fitness bands, marine use

Nylon Fair Absorbs moisture, feels clammy when wet Higher strength Vulnerable to UV, 50-60% strength loss over 36 months High-load applications only

Polypropylene webbing is more water-resistant and cost-effective, while polyester performs better under UV exposure and higher temperatures. Polyester also maintains better shape retention and doesn’t stretch as much. Polyester is about 90% as durable as nylon and is one of the most UV-stable webbings available, making it excellent for outdoor applications.

Design Takeaway: Choose polyester mesh webbing when breathability is critical for user comfort, understanding that mesh requires more careful edge finishing during production. Use solid polyester when you need moderate breathability with standard manufacturing methods, and consider polypropylene for budget-conscious applications where UV exposure is limited.

For armbands, choose non-elastic webbing for devices over 4 ounces or all-day wear, and elastic webbing (10-15% elastane content) for lightweight devices under 2 ounces requiring frequent adjustment. Polyester stays put under tension with no sagging or loosening over time, providing rock-solid stability. Elastic webbing typically costs 15-25% more due to elastane fiber content.

Decision Framework by Application:

From our manufacturing experience, elastic webbing presents durability challenges. Elastane fibers degrade 20-30% within 6-12 months when exposed to sweat and washing. Hardware compatibility also differs—elastic webbing requires spring-loaded buckles or stretchy closures, while non-elastic works with standard cam buckles, side-release buckles, and ladder locks.

Hardware Compatibility Guide:

Design Takeaway: Specify non-elastic polyester with cam buckle closures for maximum durability and device security. Use elastic only when consistent skin contact trumps long-term durability, and always plan replacement intervals.

For extended comfort, use 0.065-0.070 inch thick webbing, which works with standard 1-2 inch hardware while distributing pressure evenly. Standard webbing at 0.047 inches (1.2mm) thick works for short-duration use but creates pressure points during all-day wear. Thicker webbing beyond 0.080 inches requires oversized hardware.

Thickness Guidelines by Wear Duration:

Manufacturing considerations become critical with thickness changes. Thicker polypropylene webbing feels softer and more flexible, but requires industrial sewing machines for clean edge finishing. Standard domestic machines handle up to 0.070 inches; beyond that needs heavy-duty equipment and specialized needles.

Hardware Compatibility by Thickness:

Edge finishing methods also change with thickness. Heat-sealing works well up to 0.070 inches; thicker webbing requires folded and sewn edges or ultrasonic welding to prevent fraying and skin irritation.

Design Takeaway: Target 0.065-0.070 inch thickness for extended wear comfort using standard hardware. Plan for industrial sewing equipment and specialized edge finishing if specifying thicker webbing for ultra-long wear applications.

Match webbing width to device weight: 1 inch for <2 oz devices, 1.5 inches for 2-6 oz devices, and 2 inches for 6+ oz devices to prevent rotation and ensure stability. Wider webbing provides higher break strength and distributes load across more contact area, reducing pressure concentration during movement.

Device Weight to Width Chart:

Device Weight Webbing Width Typical Applications

<2 oz 1″ Fitness trackers, small sensors

2-4 oz 1.25″ Large smartwatches, compact phones

4-6 oz 1.5″ Standard smartphones, medical devices

6-8 oz 2″ Large phones, multi-sensor devices

>8 oz 2.5″+ Tablet holders, heavy equipment

Standard hardware availability constrains width choices. Most suppliers stock buckles, slides, and D-rings in 1″, 1.25″, 1.5″, and 2″ widths. Custom widths (1.75″, 2.25″) require special orders with higher minimums and longer lead times.

Manufacturing efficiency favors standard widths. Webbing looms run most economically in 1″, 1.25″, 1.5″, 2″, and 3″ widths. Custom widths increase material waste and setup costs by 20-40%. Additionally, most industrial sewing machines handle 1-2 inch webbing efficiently; wider widths may require specialized equipment.

Standard Hardware Availability:

Design Takeaway: Use standard widths (1″, 1.5″, 2″) for optimal hardware availability and manufacturing efficiency. Size up to the next standard width rather than specifying custom dimensions to control costs and lead times.

Most armband applications need 300-500 lbs breaking strength webbing to handle typical device weights of 2-8 ounces with adequate retention security. 1-inch nylon webbing provides 1,150-2,390 lbs breaking strength, while 1-inch polypropylene webbing offers 600-900 lbs, both exceeding armband requirements significantly.

Device Weight to Breaking Strength Guide:

Device Type Device Weight Recommended Breaking Strength Webbing Options

Fitness trackers 1-2 oz 300-400 lbs Polypropylene, polyester

Smartphones 4-8 oz 400-600 lbs Polyester, light nylon

Medical devices 3-6 oz 500-700 lbs Polyester, nylon

Work badges 1-3 oz 300-500 lbs Polypropylene adequate

From our manufacturing perspective, attachment method affects load distribution more than raw strength. Knots reduce strength by 25-50% depending on type , but armbands typically use sewn loops or hardware closures that maintain full webbing strength.

The primary failure mode in armbands isn’t webbing breakage but device slippage due to inadequate friction or loose closure systems. Even lightweight polypropylene webbing at 700 lbs breaking strength provides 100x safety margin over typical smartphone weight. Focus on closure security and fit rather than maximum webbing strength.

Design Takeaway: Standard polypropylene or polyester webbing provides massive load margins for all typical armband applications. Choose material based on UV resistance and cost rather than strength requirements.

Mesh webbing provides adequate strength for armband applications, with tensile strength between 500-1,000 lbs for widths from 1/2″ to 2″ – exceeding requirements for all typical armband devices. The open-weave structure delivers superior breathability while maintaining structural integrity.

The reinforcing substrate provides tensile strength while coating adds durability, creating a composite material that balances airflow with load capacity. Mesh construction distributes stress across multiple fiber intersections rather than relying on continuous strand strength.

Progressive unraveling from cut edges represents the main failure risk with mesh webbing. The interconnected weave pattern means edge damage can propagate inward over time. Heat-sealing synthetic mesh edges during manufacturing prevents this failure mode effectively.

Breathability advantages of mesh typically outweigh strength differences for armband applications. The 500-pound minimum strength of mesh webbing still provides 50-100x safety margin over actual device loads, making airflow the determining factor rather than load capacity.

Design Takeaway: Prioritize mesh webbing when user comfort and breathability matter most. The strength difference between mesh and solid webbing becomes irrelevant when both exceed device requirements by massive margins.

For armband applications, target 20-30% stretch to accommodate fit adjustment without allowing device movement during activity. Elastic webbing with 27% rubber latex content provides up to 40% stretch and excellent memory, while standard elastic polyester webbing provides 90% stretch – both exceeding armband needs.

Stretch Requirements by Application:

Application Optimal Stretch Reason Material Choice

Medical sensors 15-25% Stable contact needed Low-stretch elastic

Fitness trackers 20-30% Balance comfort/security Standard elastic

Smartphone bands 25-35% Accommodation for cases Medium-stretch elastic

Adjustable badges 30-40% Frequent size changes Higher-stretch elastic

Recovery decreases with increasing number of cycles, and elastomeric yarn loses recovery ability over time making durability considerations important for frequently adjusted armbands. Excessive stretch capability (>40%) compromises device stability as arm muscles expand and contract during exercise.

From our manufacturing experience, elastic webbing is woven rather than braided, giving stronger construction that retains width when stretched. This construction method provides consistent performance across the stretch range, preventing the narrowing that occurs with braided elastic under tension.

Design Takeaway: Specify 25-30% stretch for optimal armband performance – enough accommodation for fit variation without compromising device security. Higher stretch percentages risk device shifting during movement.

Polypropylene webbing excels in moisture environments, highly water-resistant and does not absorb moisture, making it ideal for outdoor use and marine environments, while nylon absorbs moisture and weakens when.

Moisture Decision Guide:

Material Water Absorption Best For Avoid When

Polypropylene Does not absorb moisture Sweat exposure, marine use Indoor-only applications

Polyester Under 1% weight absorption General outdoor use Extreme humidity

Nylon Absorbs moisture, decreases strength Dry environments only Any moisture exposure

From manufacturing experience, polypropylene webbing is not affected by oils, chemicals, and acids, making it superior for sweat contact. Polyester maintains strength and structural integrity after repeated soak-dry cycles but shows gradual degradation in high-humidity environments.

Sweat creates more challenges than general moisture due to salt and oil content. Polypropylene dries quickly when exposed to water and doesn’t retain body salts that cause material degradation over time.

Selection Criteria:

Design Takeaway: Polypropylene provides best moisture resistance for armband applications involving sweat or humidity exposure. Polyester works for moderate outdoor use but degrades faster in high-moisture conditions.

Cotton webbing offers best skin compatibility, hypoallergenic and breathable, minimizing risk of skin irritation, while polyester can trap heat and moisture, leading to skin irritation and is treated with various chemicals during production.

Skin Safety Decision Framework:

Material Skin Safety Strength Use When

Cotton Hypoallergenic, soft texture Lower Device under 3 oz, short wear

Polypropylene Minimizes skin irritation Moderate Extended wear, lightweight devices

Polyester Can cause allergic reactions Highest Non-skin contact applications

No government regulations exist for hypoallergenic fabrics, meaning companies can label products hypoallergenic based on their own standards. This makes material selection critical rather than relying on marketing claims.

Cotton’s lower strength requires design considerations. For devices over 4 ounces, consider cotton webbing with reinforced stitching at attachment points or polypropylene as a compromise between skin safety and strength.

Material Selection Rules:

Design Takeaway: Cotton provides best skin compatibility but requires strength reinforcement for heavier devices. Polypropylene offers good skin tolerance with better strength for extended-wear applications.

Perforating webbing for breathability significantly reduces strength and creates failure points, making it unsuitable for device-bearing applications. Mesh construction results in a breathable, lightweight fabric for ventilation applications while maintaining structural integrity through intact fiber load paths.

Unlike perforated metal that offers high strength-to-weight ratio, cutting holes in woven webbing disrupts load-bearing fibers. Each perforation creates stress concentration points where failure typically initiates under load. Manufacturing perforated webbing requires laser cutting after weaving, increasing cost 40-60% while reducing strength by 50-70%.

Never Perforate When:

Better Breathability Solutions: Mesh webbing provides superior airflow through engineered open-weave construction during manufacturing rather than post-production cutting. Surface texturing creates airflow channels without severing fibers, maintaining 90-95% of original strength. Strategic design uses solid webbing at stress points with breathable sections in non-critical areas.

From our manufacturing perspective, most webbing facilities don’t offer perforation services due to specialized laser equipment requirements. Mesh webbing uses standard looms with modified weave patterns, keeping costs reasonable while delivering superior breathability performance.

Manufacturing Reality: Perforation weakens webbing unpredictably – failure can occur at perforations well below rated loads. Quality control becomes complex since each hole affects surrounding material differently.

Design Takeaway: Specify engineered mesh webbing for armband breathability rather than requesting perforation of solid webbing. Mesh delivers superior airflow without compromising structural integrity or requiring specialized manufacturing processes.

Breathable armband design requires balancing material properties with user comfort and device security. Polyester mesh provides optimal breathability for most applications, while polypropylene excels in moisture-heavy environments. Non-elastic webbing with proper thickness and width specifications ensures long-term performance.

Contact us to explore manufacturing solutions tailored to your armband requirements.

Request OEKO-TEX Standard 100 certified webbing, which ensures materials are tested for harmful substances. Cotton webbing provides the most hypoallergenic option, while untreated polypropylene offers good skin compatibility with higher strength.

Polyester maintains 67%+ strength after 12 months sun exposure. Polypropylene offers good UV resistance but nylon degrades significantly under prolonged sunlight without treatment.

Mesh webbing typically provides 20-30% less strength than solid webbing of equivalent width, but still offers 500-1,000 lbs breaking strength – adequate for all armband applications.

0.065-0.070 inch thickness distributes pressure evenly for 8+ hour wear periods. Thinner webbing creates pressure points while thicker options become bulky and restrict movement.

400-600 lbs breaking strength handles smartphones weighing 4-8 ounces with adequate safety margins. Standard polyester or polypropylene webbing exceeds these requirements significantly.

10% elastane provides approximately 25% stretch suitable for medical devices. 25% elastane delivers 40%+ stretch but risks device movement during activity – avoid for armband applications.