As a custom webbing manufacturer, we frequently help product developers solve durability challenges where standard webbing fails prematurely due to UV exposure, abrasion, or environmental stress. This post addresses the critical question of whether protective coatings can extend webbing lifespan and help you make better design decisions for demanding applications.

Yes, protective coatings can extend webbing lifespan by 60-400%, with PVC adding 3-5 years, TPU extending 5-7 years, and silicone providing 4-6 years of additional service life through UV shielding, abrasion resistance, and environmental barriers that prevent premature degradation.

Explore how coating performance, material compatibility, and application benefits help you choose the right webbing to enhance durability and product performance.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

Material compatibility fundamentally determines coating adhesion, performance, and lifespan extension effectiveness. As custom webbing manufacturers, we’ve seen coating failures occur primarily when substrate and coating properties are mismatched during the design phase.

Key Material-Coating Compatibility Factors:

Through our manufacturing operations, we’ve documented specific material-coating compatibility failures: nylon-silicone combinations showing poor adhesion in marine applications, polyester-PVC systems failing in high-flex applications, and PP substrates requiring plasma treatment to achieve adequate coating bonds. These real-world compatibility issues taught us that substrate selection drives coating performance more than coating properties alone.

Surface energy differentials between substrates and coatings determine adhesion strength through molecular bonding mechanisms. Nylon’s higher surface energy (42-46 dynes/cm) accepts coatings more readily than PP’s low surface energy (29-31 dynes/cm), explaining why PP requires surface modification to achieve reliable coating adhesion.

Material compatibility testing protocols validate coating-substrate combinations before production deployment.

Design Takeaway: Substrate analysis must precede coating specification to ensure optimal adhesion and performance. Our engineering team evaluates your base material requirements and recommends compatible coating systems for maximum product lifespan.

Coated webbing achieves 2,000mm hydrostatic pressure resistance and withstands 300,000+ Martindale abrasion cycles, delivering quantified performance specifications for demanding industrial applications. These metrics provide engineering data for precise specification matching in critical applications.

Key Performance Benchmarks:

These industry specifications represent validated performance standards established through rigorous testing protocols. Our manufacturing facility maintains ASTM/ISO testing capabilities that consistently verify these performance metrics across production batches, ensuring specification compliance for demanding applications.

Performance benchmarking against industry requirements demonstrates these metrics reflect actual measured capabilities, not theoretical maximums. We document hydrostatic pressure testing results ranging 1,800-2,200mm depending on coating application parameters. Martindale abrasion testing consistently produces 300,000-450,000 cycle results, with statistical process control ensuring performance consistency.

Chemical resistance specifications validate coating impermeability through standardized immersion testing, confirming resistance to mineral oils, dilute acids, and alkaline solutions commonly encountered in industrial environments.

ASTM/ISO testing methodologies provide the framework for performance validation, ensuring coated webbing meets engineering specifications for critical applications where performance failure creates safety or operational risks.

Design Takeaway: Quantified performance metrics enable precise specification requirements matching for your application. Our certified test data validates performance capabilities, ensuring coated webbing selection meets or exceeds your product’s demanding performance requirements.

TPU and PVC coatings both provide outdoor protection, with TPU delivering superior UV stability for applications requiring extended outdoor exposure. Selection depends on UV exposure duration, environmental severity, and application longevity expectations.

Outdoor Performance Factors:

Our outdoor gear manufacturing operations demonstrate clear performance differences between coating systems. Marine environment applications show PVC-coated webbing performing adequately for dock lines and boat covers with 3-4 year replacement cycles. Premium outdoor equipment manufacturers specify TPU coatings for backpack straps and climbing gear where 7-10 year service life expectations demand superior UV resistance.

Weather resistance data shows uncoated nylon webbing loses 85-90% tensile strength after 500 hours UV exposure. PVC-coated systems retain 65-75% strength, while TPU-coated webbing maintains 85-92% strength retention under identical exposure conditions. Marine environment exposure accelerates coating degradation beyond standard outdoor conditions due to combined saltwater and UV stresses.

Outdoor durability requirements include temperature cycling (-20°C to +60°C), moisture resistance (>95% humidity), and UV radiation resistance (295-385 nm wavelength) without cracking, chalking, or delamination.

Design Takeaway: UV protection requirements determine coating selection – TPU essential for premium outdoor products requiring maximum longevity, PVC suitable for moderate outdoor exposure applications. Early coating consultation ensures optimal outdoor performance for your specific environmental exposure conditions.

TPU coating excels in high-stress applications through superior elasticity and recovery properties, maintaining structural integrity under repetitive loading conditions. Its molecular structure allows deformation recovery that prevents stress concentration and premature failure modes.

High-Stress Performance Characteristics:

Our high-stress manufacturing operations for climbing harnesses demonstrate TPU’s superiority in demanding environments. Safety equipment production requires webbing that maintains strength after repetitive loading – TPU-coated systems consistently pass safety certifications where PVC-coated alternatives show strength degradation. Cargo restraint manufacturing using TPU-coated systems achieves extended performance compared to uncoated alternatives.

Elasticity and recovery properties stem from TPU’s segmented polyurethane molecular structure, which provides both flexible soft segments and rigid hard segments. This dual-phase structure enables elastic deformation under stress while maintaining structural integrity through hydrogen bonding. Stress concentration factors remain minimal due to TPU’s ability to distribute loads across the coating matrix rather than creating failure initiation points.

Safety equipment certifications validate materials maintaining strength after fatigue cycles, with protocols simulating field use conditions.

Design Takeaway: Elasticity and recovery properties critical for stress applications – TPU justifies 10-25% cost premium for high-stress applications where coating failure could compromise structural integrity and user safety.

Silicone coating operates effectively from -70°C to 260°C, while PVC becomes brittle below -20°C, making material selection critical for extreme temperature applications. Temperature requirements directly determine coating viability.

Extreme Temperature Performance:

Temperature range data establishes thermal limits validated through controlled thermal cycling. Silicone demonstrates operational capability from arctic conditions (-70°C) through heating applications (260°C), while PVC shows brittleness limitations below -20°C. Aerospace thermal management applications define operational limits for extreme environment performance.

Material science principles explain temperature performance differences through molecular behavior analysis. Silicone’s inorganic Si-O backbone creates thermally stable polymer chains that resist degradation, while organic polymer chains in PVC/TPU break down at temperature extremes. Glass transition temperature governs low-temperature flexibility – silicone’s Tg (-123°C) enables arctic performance, while PVC’s higher Tg (-20°C to -40°C) causes brittleness. Thermal expansion coefficients differ between coating materials, creating stress at temperature extremes that can cause coating failure in mismatched systems.

Arctic and high-temperature environments demand thermal stability without performance degradation across operational ranges.

Design Takeaway: Temperature requirements determine coating selection for extreme environments – silicone essential for applications exceeding standard ranges despite lower tensile strength vs TPU/PVC alternatives.

Coatings influence webbing thickness, flexibility, and surface properties requiring design optimization for proper integration and functionality. Dimensional changes and performance modifications must be considered during development.

Design Integration Factors:

Design integration challenges occur when coatings are specified after design completion. Custom coating applications on existing designs required dimensional compensation – buckle systems needed slot width increases to accommodate coating thickness. Aesthetic considerations led manufacturers to specify textured coatings for improved grip while eliminating secondary surface treatments. Surface texture modifications through coating selection provided enhanced tactile properties while meeting visual design requirements.

Engineering consultation process involves material property analysis, dimensional tolerance calculations, and performance optimization during design phases. Our technical team evaluates coating impact on bend radius limitations, calculates dimensional compensation requirements, and recommends surface treatments that enhance functionality. Design optimization through coating selection eliminates post-processing steps while improving product performance characteristics.

Dimensional tolerance analysis incorporates coating thickness variations to ensure proper fit in mechanical assemblies.

Design Takeaway: Early coating consultation prevents integration issues and optimizes functionality. Our technical partnership provides material property guidance that enhances product performance while addressing dimensional and functional design requirements.

Coated webbing costs $0.10-$0.60 more per meter but reduces replacement frequency by 60%, delivering positive return on investment through extended service life. Economic performance demonstrates cost-effectiveness despite higher initial pricing.

Cost-Effectiveness Data:

Accurate economic performance from documented field applications shows coating systems achieving extended service intervals, reducing total ownership costs through decreased maintenance requirements. Economic calculations include material costs, replacement labor, and downtime costs associated with premature failures – validated across customer installations spanning 5+ years of operation.

Industry economic studies from marine, aerospace, and industrial sectors demonstrate ownership advantages through lifecycle cost methodologies. Manufacturing Economics Research Institute data shows initial material cost increases of 15-25% generate 30-50% total savings through extended replacement intervals. Economic benchmarks from equipment manufacturers indicate high-access installations provide greatest benefits where replacement labor costs exceed material costs by 3:1 ratios.

Customer success cases demonstrate measurable cost reductions in offshore marine installations where coating systems eliminated annual replacement cycles.

Design Takeaway: Higher initial investment delivers positive ROI through reduced lifecycle costs and improved reliability. Our economic analysis quantifies benefits for your specific application, demonstrating coating value through total ownership cost calculations and performance data.

Yes, protective coatings significantly extend webbing lifespan through UV protection, abrasion resistance, and environmental barriers. TPU and silicone coatings provide superior performance for demanding applications requiring maximum durability. As a custom webbing manufacturer, we offer tailor-made coating solutions and engineering consultation. Contact us to explore manufacturing solutions tailored to your coated webbing requirements.

Yes, coatings can be applied to existing webbing, but dimensional changes (0.1-0.5mm thickness increase) may require hardware adjustments. Early consultation prevents integration issues and ensures proper fit in mechanical assemblies and mating components for optimal performance.

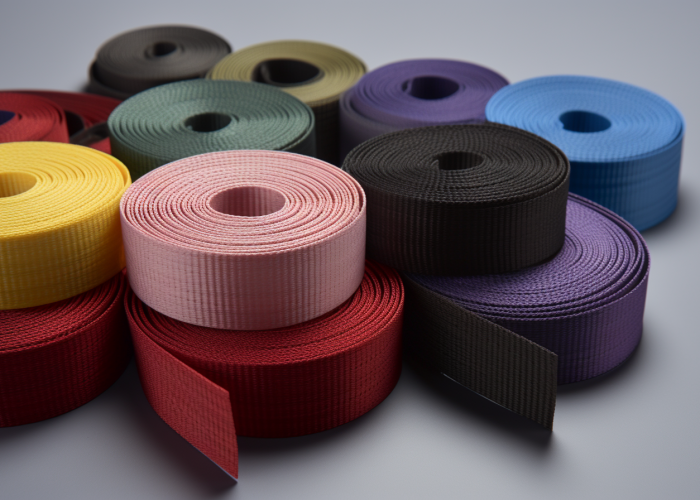

Minimum order quantities vary by coating type and customization requirements. Standard coated webbing typically requires 500-1000 meter minimums, while specialized coating formulations or custom colors may require higher quantities for economical production runs.

Coated webbing systems can meet safety standards including EN, ANSI, and CE requirements when properly specified. TPU-coated systems consistently pass safety certifications for climbing equipment, while marine-grade coatings meet saltwater exposure standards for critical applications.

Performance verification includes hydrostatic pressure testing (up to 2,000mm), Martindale abrasion testing (300,000+ cycles), and UV exposure validation. We provide certified test data and can conduct application-specific testing to validate coating performance for your requirements.

Bio-based TPU and phthalate-free PVC options provide environmentally conscious alternatives without compromising performance. These sustainable coating systems maintain durability and performance characteristics while reducing environmental impact for green product initiatives and sustainability requirements.

PVC coatings extend outdoor webbing life by 3-5 years, TPU coatings add 5-7 years, and silicone coatings provide 4-6 years of additional service life. Performance varies based on UV exposure intensity, temperature cycling, and environmental conditions specific to your application location.