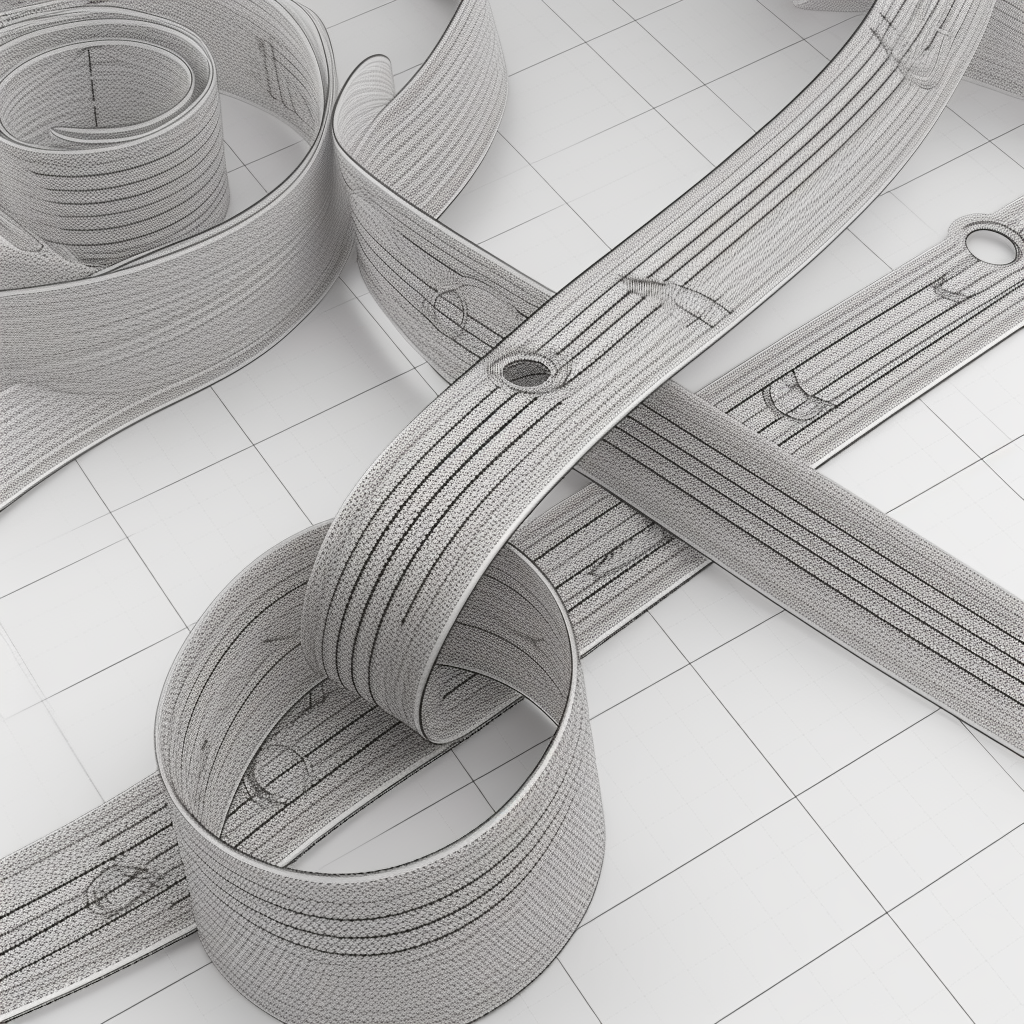

Custom webbing is tailored to specific requirements, from material choices like polyester to unique printed designs, ensuring it meets individual or business needs.

Polyester webbing is known for its UV resistance and durability, making it a preferred choice for outdoor applications compared to some other materials.

Absolutely! Many manufacturers specialize in custom-printed webbing, allowing you to incorporate graphic designs, logos, and unique patterns to align with your brand.

The process typically involves:

- Selecting the material.

- Providing the desired graphic or logo.

- Working with a design team to ensure the print aligns with your vision.

Yes, elastic can be integrated into the webbing for applications that require stretch and flexibility.

Consider the end-use of the webbing. For instance, a climbing harness might require a different length and strength than a fashion belt. It’s important to note your requirements and consult with the manufacturer.

Production factors include material availability, design complexity, and the preferred timeline. It’s advisable to request samples before a full production run.

Custom ribbon webbing often focuses on aesthetic appeal, incorporating intricate patterns and designs, while traditional webbing might prioritize function over form.

Most specialized manufacturers provide a comparison of materials, detailing factors like durability, elasticity, and suitability for specific applications.

The timeline can vary based on design complexity and manufacturer capacity. However, after design approval, production usually takes a few weeks, but always confirm lead times with your chosen manufacturer.