As a custom webbing manufacturer, we regularly help product developers resolve confusion about grip webbing terminology and selection. This post clarifies whether grip and non-slip webbing are different products, guides coating selection for specific applications, and identifies performance standards that prevent costly design failures. Our tailor-made webbing solutions across safety, outdoor, and industrial applications provide the technical insights needed for informed material decisions.

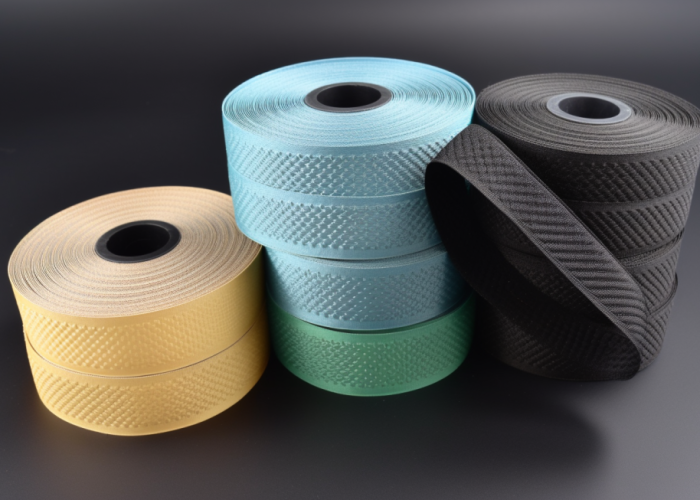

Yes, grip webbing and non-slip webbing are the same product—these terms simply represent different marketing approaches for identical friction-enhanced webbing materials. Both describe webbing treated with specialized coatings, textures, or integrated materials to increase surface friction and prevent slippage under load.

Get expert guidance on coating selection, grip specs, and compliance to optimize materials using proven engineering and manufacturing data.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

Yes, grip webbing and non-slip webbing are the same product—both terms describe identical friction-enhanced webbing materials with surface treatments to prevent slippage. The terminology difference stems from marketing preferences across industries rather than distinct manufacturing processes or performance characteristics.

Key similarities include:

Industry data shows that over 80% of manufacturers use “non-slip” terminology for safety applications, while “grip” is preferred for outdoor and sports equipment. From our manufacturing experience, the confusion often arises because different market segments developed separate vocabularies for the same technology. Safety harness manufacturers typically specify “non-slip webbing” in technical documentation, while backpack companies request “grip webbing” for shoulder straps. We apply identical coating processes and quality standards to produce both products, regardless of customer terminology.

Design Takeaway: Focus on specifying friction coefficient requirements (typically 0.7-0.9), environmental conditions, and surface enhancement method rather than using marketing terminology. Clear performance specifications ensure you receive the correct material regardless of how suppliers label their products.

Grip webbing is used for safety harnesses, outdoor equipment, industrial load securing, and consumer products where slip prevention is critical for performance or safety. These applications span from life-critical safety equipment to everyday consumer products requiring reliable grip performance.

Primary application categories include:

From our manufacturing experience, safety applications demand the highest performance standards to meet OSHA and ANSI regulatory requirements. Outdoor equipment prioritizes durability against UV exposure and moisture, making weather resistance crucial for backpack and climbing gear manufacturers. Industrial load securing focuses on maximum strength and abrasion resistance for heavy-duty cargo applications.

Environmental considerations vary significantly by application category. Marine equipment requires salt water resistance, while automotive applications need temperature cycling performance. Consumer products often balance grip performance with user comfort and adjustability requirements.

Design Takeaway: Identify your application category first—safety, outdoor, industrial, or consumer—then specify environmental conditions and regulatory requirements. Each category has distinct performance priorities that influence material selection and coating specifications.

PVC coatings offer the best cost-to-performance ratio for indoor applications, while silicone excels in wet conditions, TPU handles temperature extremes, and rubber provides maximum grip strength. Coating selection depends on environmental exposure, temperature range, and required friction coefficient for your specific application.

Performance comparison by coating type:

Our manufacturing data shows critical performance differences across environmental conditions. Silicone maintains grip performance in wet conditions while PVC drops to 60% effectiveness when moisture is present. TPU demonstrates superior performance in temperature cycling tests, retaining flexibility after 1000 freeze-thaw cycles. Rubber integration provides maximum friction but shows faster UV degradation without stabilizers.

Environmental testing reveals that marine applications require silicone or TPU for salt water resistance, while industrial environments with chemical exposure benefit from TPU’s superior chemical compatibility. Outdoor equipment exposed to UV radiation performs best with solution-dyed TPU or stabilized rubber formulations.

Design Takeaway: Select PVC for cost-sensitive indoor applications, silicone for wet environments, TPU for temperature extremes or chemical exposure, and rubber for maximum grip requirements. Consider environmental testing requirements and total cost of ownership when specifying coating type.

Safety applications require a minimum friction coefficient of 0.7, with critical applications like fall protection harnesses needing 0.8-0.9 for regulatory compliance. These specifications ensure reliable grip performance under load conditions where slip failure could result in serious injury or fatality.

Friction requirements by safety application type:

From our manufacturing experience with safety equipment producers, friction testing must account for real-world conditions including moisture, temperature variation, and repeated loading cycles. ASTM D1894 testing protocols measure static and kinetic friction under controlled conditions, but field performance often differs due to contamination, wear, and environmental factors.

Safety margin calculations typically require 20-30% higher friction coefficients than theoretical minimums to account for degradation over service life. Regulatory inspections focus on both initial performance and retained performance after accelerated aging tests. Emergency rescue applications often specify the highest friction requirements due to life-critical consequences of grip failure.

Testing methodology involves dry and wet condition measurements, with acceptance criteria requiring consistent performance across temperature ranges specified for the application environment.

Design Takeaway: Specify minimum friction coefficients with safety margins—use 0.8+ for fall protection, 0.7+ for restraint systems, and include both dry and wet performance requirements. Reference applicable OSHA, ANSI, or CE standards in your material specifications for regulatory compliance.

Grip webbing typically lasts 3-5 years in outdoor applications and 5-10 years in indoor environments, depending on coating type, UV exposure, and usage intensity. Proper material selection and environmental protection significantly extend service life and maintain grip performance over time.

Lifespan by coating type and environment:

Our accelerated aging testing shows that UV exposure reduces grip coating effectiveness by 15-25% annually in direct sunlight applications. Temperature cycling between -20°F and 180°F causes coating flexibility loss, while abrasion from repeated use creates surface wear that reduces friction performance. Marine environments with salt exposure accelerate degradation by 30-40% compared to freshwater conditions.

Performance monitoring involves regular friction testing and visual inspection for coating delamination, cracking, or surface wear patterns. Predictive maintenance schedules based on usage hours and environmental exposure help prevent grip failure before safety margins are compromised.

Design Takeaway: Factor replacement schedules into product lifecycle costs—budget for 3-5 year replacement in harsh outdoor environments or 5-10 years for protected indoor use. Specify UV-stabilized coatings for outdoor applications and establish inspection protocols to monitor grip performance degradation over time.

OSHA 1926.95 applies to workplace safety harnesses, ANSI Z359 covers fall protection equipment, CE EN 361 governs European harness standards, and REACH regulates chemical compliance for all coatings. Compliance requirements vary by application, market region, and end-use safety classification.

Key standards by application category:

From our manufacturing experience with certified products, testing protocols require friction coefficient verification under specific load conditions. ANSI Z359.11 mandates 0.8 minimum friction for harness webbing, while OSHA construction standards specify performance retention after UV exposure and moisture cycling. European CE marking requires third-party testing and ongoing quality system audits.

Certification processes involve initial type testing, production quality control, and periodic retesting to maintain compliance. Documentation requirements include material certificates, test reports, and traceability records for regulatory inspections. REACH compliance affects coating material selection, requiring detailed chemical composition disclosure for European markets.

Testing laboratories must be accredited to ISO/IEC 17025 standards, with specific expertise in textile and webbing performance evaluation. Compliance costs typically range from $5,000-15,000 for initial certification plus ongoing quality system maintenance.

Design Takeaway: Identify applicable standards early in design phase—safety applications require extensive testing and certification, while consumer products may need only basic compliance. Budget for certification costs and ongoing quality system requirements when planning market entry timelines.

Grip webbing fails due to inadequate friction coefficient specification, wrong coating selection for environmental conditions, poor integration design, or insufficient quality control during manufacturing. Most failures are preventable through proper material selection and design validation before production.

Common failure modes and root causes:

Our manufacturing analysis of failed applications shows that 60% of grip webbing failures result from environmental mismatch—specifying indoor-rated coatings for outdoor use or selecting moisture-sensitive materials for marine applications. Design integration problems account for 25% of failures, typically involving sharp edges, pinch points, or inadequate stress distribution that concentrates wear.

Quality control failures during production include insufficient coating adhesion testing, inadequate cure time, or contamination during application. Field failures often trace back to missing environmental testing or inadequate accelerated aging validation before product launch.

Prevention strategies involve comprehensive environmental testing, proper coating selection for actual use conditions, and design validation under worst-case loading scenarios. Material specifications should include safety margins for friction performance and environmental exposure limits.

Design Takeaway: Validate grip webbing performance under actual use conditions before production—test environmental exposure, loading cycles, and wear patterns. Specify coating type based on worst-case environmental conditions and include quality control testing for coating adhesion and friction verification during manufacturing.

Grip and non-slip webbing are identical products with different terminology—focus on specifying friction coefficients and environmental requirements rather than marketing names. Silicone and TPU coatings provide superior performance for demanding applications compared to standard PVC options. Contact us to explore manufacturing solutions tailored to your grip webbing requirements.

Safety-critical products require 0.8-0.9 friction coefficient minimum to meet OSHA and ANSI standards for fall protection equipment. Non-critical applications like consumer straps can use 0.6-0.7 coefficient, while industrial load securing needs 0.7+ for reliable cargo restraint performance.

Custom grip webbing minimum orders typically range from 1,000-5,000 yards depending on coating type and width specifications. Standard grip webbing products often have lower minimums of 500-1,000 yards, while specialized formulations or unique textures require larger production runs for cost efficiency.

Grip webbing typically costs 40-80% more than standard webbing, depending on coating type and application method. PVC coatings add the least cost premium, while rubber integration and specialized TPU formulations command higher prices due to material and processing complexity.

Request friction coefficient test certificates, coating adhesion test results, and batch quality control documentation from your supplier. Establish incoming inspection protocols including visual examination for coating uniformity and spot-check friction testing on representative samples from each production lot.

Yes, ASTM D1894 friction testing and accelerated aging tests can verify performance on sample materials before production commitment. Most manufacturers provide test samples and can conduct third-party laboratory testing to validate friction coefficients and environmental performance for your specific application requirements.

For outdoor applications, specify silicone or TPU coatings for UV resistance and temperature stability, while indoor products can use cost-effective PVC coatings. Outdoor environments require coatings that maintain friction performance despite moisture, temperature cycling, and UV exposure over 3-5 year service life.