As a custom webbing manufacturer specializing in non-slip solutions, we regularly help product developers navigate the complex landscape of grip-enhanced materials and coating technologies. Many engineers struggle with selecting the right non-slip webbing combination for their specific applications, often facing trade-offs between performance, cost, and regulatory compliance. This comprehensive guide addresses these design challenges by providing the technical insights and practical recommendations needed to optimize your product’s safety and functionality through informed material selection.

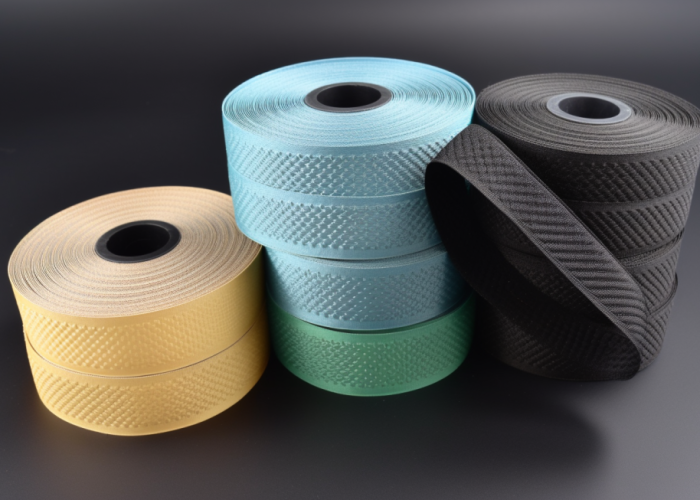

Non-slip webbing uses nylon, polyester, or polypropylene combined with grip coatings like PVC, silicone, or rubber to prevent slippage. It is used in safety, medical, outdoor, and consumer products where secure hold is essential. Material choice depends on friction level, environmental exposure, durability, and compliance requirements.

Get performance comparisons, application tips, and cost insights to choose the right non-slip webbing—plus expert guidance to optimize your design.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

Non-slip webbing combines three base materials—nylon, polyester, and polypropylene—with four coating types: PVC, silicone, TPU, and rubber. Material compatibility and application requirements determine the optimal combination for grip performance.

Key Material Performance Data:

From our manufacturing experience, material pairing significantly impacts performance and failure rates. Nylon absorbs 6-7% of its weight in water and weakens in damp environments Polyester Webbing, making it unsuitable for marine use without protective coatings. We’ve seen coating delamination when PVC is applied directly to untreated nylon, while silicone requires primer treatments—skip this and expect failure within 6-12 months outdoors.

Polypropylene resists oils, chemicals, and acids, but its lower melting point creates processing challenges. TPU coating applications fail on polypropylene when processing temperatures exceed 300°F, causing substrate melting and complete product loss.

Industry testing following ASTM standards shows 1-inch nylon achieves 3,000-4,000 pounds breaking strength Polyester Webbing, while ASTM D751 and ISO 2060 establish coating adhesion and tensile testing protocols. However, real-world performance often drops 40-60% from laboratory results due to UV exposure, chemical contact, and cyclic loading.

Design Takeaway: Base material selection must account for coating compatibility and environmental limitations. Polyester + PVC excels in UV-exposed industrial settings, nylon + silicone works for medical applications with proper primer treatment, while polypropylene + rubber provides cost-effective chemical resistance requiring low-temperature processing.

Polyester webbing with PVC or TPU coatings delivers optimal outdoor performance due to superior UV resistance and dimensional stability. Polyester initially loses 30% strength under UV in the first year then stabilizes, while nylon loses 50-60% after 36 months. Solution-dyed polyester maintains structural integrity and color fastness across outdoor temperature cycles.

Key Outdoor Performance Data:

Polyester’s superior UV resistance comes from its chemical structure containing aromatic rings that better absorb and dissipate UV energy, preventing chain scission that causes nylon degradation. This molecular advantage translates to predictable performance curves—polyester’s initial 30% strength loss represents surface oxidation, after which the material stabilizes with minimal further degradation. In outdoor equipment applications, this creates reliable long-term performance where polyester maintains load ratings above safety margins across multiple seasons of UV exposure.

Coating adhesion mechanisms differ significantly between materials. PVC creates mechanical bonds through polymer chain entanglement with polyester’s surface, achieving 15+ lbs/inch peel strength per ASTM D751 requirements. However, PVC’s glass transition temperature at -20°F causes brittleness in alpine conditions. European outdoor brands specify REACH-compliant UV stabilizer packages containing benzotriazole compounds that absorb 290-400 nm wavelengths, meeting EU chemical safety requirements and extending performance by 40-60% in Mediterranean climates.

Design Takeaway: Use polyester + PVC coating for cost-effective outdoor applications, polyester + TPU coating for premium temperature performance. Factor in 30% initial strength loss during first-year calculations, then design for stable performance. Include REACH-compliant UV stabilizer packages and implement replacement schedules based on cumulative UV dose rather than calendar time.

Silicone coating provides superior temperature performance (-65°F to 400°F) and chemical resistance for safety applications, while rubber coating delivers higher baseline friction coefficients for enhanced grip. Safety-critical applications requiring temperature extremes or chemical exposure favor silicone, while standard industrial environments benefit from rubber’s cost-effective grip enhancement.

Key Safety Performance Data:

Friction coefficient differences stem from molecular surface interactions and deformation mechanisms. Rubber coatings achieve higher friction through viscoelastic hysteresis—energy dissipation during surface deformation creates grip through micro-interlocking. Silicone’s lower surface energy (20-24 dynes/cm) reduces adhesive friction compared to rubber’s 30-40 dynes/cm, but silicone maintains consistent performance across temperature ranges where rubber becomes either too hard (cold) or too soft (hot) for reliable grip.

Critical performance analysis shows distinct degradation patterns between materials. Rubber coatings experience thermal breakdown above 200°F through crosslink destruction, compromising grip reliability in high-temperature environments. Silicone maintains molecular stability to 400°F through Si-O bond strength (106 kcal/mol vs C-C bonds at 83 kcal/mol), but requires surface treatments to achieve safety-critical friction levels. OSHA 29 CFR 1926.502 mandates fall protection equipment maintain minimum grip performance throughout operational life.

Design Takeaway: Use silicone coating for temperatures above 200°F or chemical exposure, rubber coating for standard industrial environments prioritizing maximum grip. Design safety margins accounting for 20-30% friction degradation over operational cycles. Implement inspection protocols measuring actual friction coefficients rather than visual assessment, and replace before performance drops below OSHA minimums.

Medical-grade silicone-coated polyester or nylon webbing meets FDA biocompatibility standards and sterilization requirements. ISO 10993-1:2018 requires complete chemical characterization and toxicological assessment, while USP Class VI involves acute systemic toxicity, intracutaneous reactivity, and implantation testing.

Key Medical Performance Data:

Platinum-cured silicones offer superior sterilization performance with lower extractables. FDA evaluates devices in final finished form, including processing methods and sterilization residuals. Our medical partnerships require comprehensive certificates from accredited laboratories following Good Laboratory Practice standards. ISO 10993 provides more comprehensive evaluation than USP Class VI minimum requirements for implant applications.

Design Takeaway: Use silicone-coated polyester for direct patient contact requiring USP Class VI, nylon for short-term contact applications. Plan 6-12 month testing timelines and implement complete material traceability systems.

Pet equipment requires 2-3x pet weight dynamic load capacity with 0.6-0.8 friction coefficients for reliable grip during sudden movements. A 10-pound pet generates 500 pounds collision force, 60-pound dogs create 3,000 pounds. Breakaway mechanisms balance restraint with animal welfare.

Key Pet Performance Data:

Panic responses generate 4-5x body weight through escape attempts. Wide strap design distributes forces effectively, preventing pressure concentration during restraint. Our manufacturing experience shows friction below 0.6 allows slippage, above 1.0 creates over-restraint preventing natural position adjustment. Crash-tested designs use padded vests and infinity loop webbing for force distribution.

Design Takeaway: Use 2-3x pet weight for normal calculations, 4-5x for panic scenarios with 0.6-0.8 friction coefficients. Design 10,000+ flex cycle durability with temperature-stable, biologically-resistant materials.

PVC offers lowest cost at $0.15-0.25/linear foot with 2-3 year lifespan, while TPU provides balanced performance at $0.40-0.65/foot lasting 5-8 years, and silicone delivers maximum durability at $0.50-0.85/foot with 8-12 year service life. Total cost of ownership calculations must factor replacement frequency, volume pricing, and application-specific performance requirements.

Key Cost Performance Data:

Without considering additional special processes, silicone pricing must be higher than TPU, mainly determined by material scarcity and manufacturing complexity. From our coating operations experience, volume economics dramatically impact unit costs—PVC coating uses standard extrusion equipment with minimal setup requirements, while silicone demands specialized temperature control and equipment modifications that increase initial manufacturing investment by 15-20%.

ROI analysis reveals different value propositions across coating types. Coated webbing with plastic coating significantly enhances wear resistance, allowing webbing to maintain integrity in high-friction environments. PVC replacement cycles every 2-3 years create ongoing costs, while TPU’s 5-8 year performance and silicone’s 8-12 year durability reduce long-term expenses despite higher initial investment.

Industry specifications determine optimal coating selection based on performance requirements versus budget constraints. Processing considerations include minimum order quantities typically requiring 1,000+ meters for custom specifications, affecting inventory planning and cash flow management.

Design Takeaway: Use PVC for cost-sensitive applications with planned 2-3 year replacement cycles, TPU for balanced cost-performance requiring 5-8 year durability, silicone for premium applications demanding maximum longevity. Factor volume pricing advantages and total cost of ownership including replacement frequency when optimizing coating selection for best ROI.

Non-slip performance testing follows ASTM D1894 coefficient of friction protocols using calibrated equipment with controlled load conditions and environmental validation. Testing requires sensitive 1-5 lb load cells with constant extension rates to measure static and kinetic friction coefficients accurately. Certification demands documented procedures, third-party validation, and compliance with industry-specific standards.

Key Testing Protocol Data:

Testing methodology requires controlled laboratory environments with standardized sample preparation procedures. Frictional properties depend on film age and surface conditions, with slip additive effects being time-dependent. Our testing facility protocols emphasize environmental conditioning—temperature, humidity, and aging effects significantly impact friction measurements and must be controlled for repeatable results.

Certification processes extend beyond basic friction testing to comprehensive performance validation. Dynamic loading simulates real-world conditions where webbing experiences multi-directional forces and cyclic stressing. Load testing protocols establish grip failure thresholds, while durability testing evaluates performance degradation over specified operational cycles.

Correlation of test results with actual performance can usually be established through validation studies, making laboratory testing meaningful for predicting field performance. Third-party accredited laboratories provide regulatory compliance documentation required for product certification and market approval.

Design Takeaway: Implement ASTM D1894 testing with calibrated load cells for baseline friction validation, supplemented by dynamic loading tests simulating actual use conditions. Use accredited laboratories for certification documentation and establish internal quality control protocols for production monitoring and performance consistency validation.

Non-slip webbing selection requires balancing base material properties, coating performance, and application requirements against cost considerations and regulatory compliance. Polyester with TPU or silicone coatings delivers optimal performance for most demanding applications, while proper testing validation ensures consistent grip performance throughout the product lifecycle. Contact us to explore manufacturing solutions tailored to your non-slip webbing requirements.

Minimum orders range from 1,000-3,000 meters depending on coating type and customization level. Standard products may have lower minimums. Lead times range from 2-4 weeks for standard items to 6-8 weeks for fully custom specifications including new tooling requirements.

Every production batch undergoes tensile strength testing, coating adhesion verification, and dimensional inspection. We maintain certificates of conformance, perform periodic friction coefficient validation, and conduct accelerated aging tests. Full traceability documentation is available for regulated applications.

Store in cool, dry conditions away from direct sunlight and chemical vapors. Keep temperature between 32-85°F with relative humidity below 70%. Avoid folding or creasing coated webbing during storage. Proper storage maintains coating integrity and prevents premature aging or performance degradation.

Yes, we offer custom color matching using Pantone references and can apply logos or text through screen printing, heat transfer, or digital printing processes. Printing capabilities depend on coating type—silicone and TPU accept most printing methods better than PVC coatings.

Our engineering team offers free consultation on material selection, coating recommendations, and application-specific requirements. We can review your design specifications, suggest optimizations, and provide performance data to support your product development and certification processes.

We handle global shipping with complete export documentation including certificates of origin, material safety data sheets, and compliance certificates. REACH, RoHS, and other regional compliance documentation available. Established logistics partnerships ensure reliable delivery worldwide with tracking and insurance options.