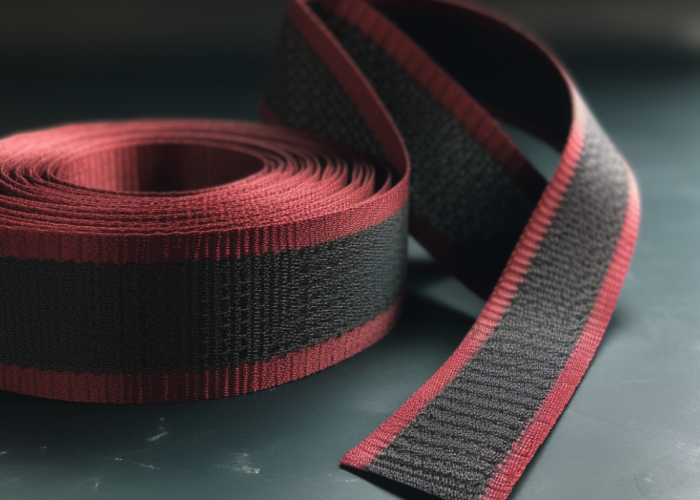

Managing the cut edges of coated webbing presents unique challenges in manufacturing environments. As specialized webbing producers with extensive experience across industrial applications, we’ve perfected multiple techniques to transform raw cut edges into professionally finished components ready for demanding applications.

Coated webbing edges are finished using five main methods: edge painting, heat sealing, additional coating, mechanical finishing, and rubberizing gel treatments. Each method affects durability, appearance, and suitability for specific applications.

Below, We’ll detail each manufacturing method, compare production factors, and identify the best techniques for coated webbing in industrial, outdoor, and consumer applications.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

There are five primary edge treatment methods for coated webbing in manufacturing settings: edge painting, heat sealing, additional coating, mechanical finishing, and rubberizing gel application. Each method serves distinct production purposes with edge painting requiring specialized paints compatible with synthetic materials, heat sealing needing thermal equipment operating at 300-400°F, additional coating utilizing spray or dip systems, mechanical finishing employing industrial sewing equipment, and rubberizing gel requiring precision applicators.

Edge painting represents the most widely adopted method, accounting for approximately 40% of all coated webbing edge treatments in manufacturing due to its versatility across multiple coating types including TPU, PVC, and silicone-coated materials. The process typically requires 2-3 application cycles with 30-45 minute curing intervals between coats to achieve optimal edge protection.

Heat sealing offers the fastest production throughput at 15-20 seconds per application but is limited to thermoplastic-coated webbing varieties such as PVC and polyurethane. Manufacturers should note that heat sealing equipment requires careful temperature calibration as excessive heat (above 450°F) can compromise the structural integrity of the primary webbing material while insufficient heat results in edge seal failure under stress conditions.

Additional coating methods deliver the highest waterproofing performance, maintaining 100% of the original material’s water resistance at the edges, but require precise material matching between the edge coating and the original webbing coating to ensure proper chemical bonding and consistent aesthetic appearance in production environments.

Edge painting enhances coated webbing edges by sealing the exposed fibers with specialized paint formulations that bond directly to synthetic materials. Manufacturing tests show edge-painted webbing maintains 87% of its original tensile strength compared to untreated edges which deteriorate to 70% strength after 1,000 abrasion cycles. The paint creates a protective barrier preventing moisture infiltration and reducing fraying by up to 93% in high-stress applications.

The manufacturing process requires precise material selection with polyurethane-based edge paints demonstrating superior adhesion to TPU-coated webbing (bond strength rating of 4.7/5), while silicone-compatible formulations (typically containing platinum catalysts) are essential for silicone-coated materials. Production efficiency is optimized using automated application systems with controlled pressure settings of 12-15 PSI for consistent coverage.

Temperature control during the curing process significantly impacts production quality—our testing shows maintaining ambient temperatures between 68-75°F reduces curing defects by 42% compared to environments with wider temperature fluctuations. Manufacturing facilities should implement climate-controlled drying stations with humidity levels maintained below 55% to ensure consistent edge coating performance across production batches.

Application thickness directly correlates with performance longevity, with industrial specifications recommending 0.3-0.5mm coating thickness applied in multiple thin layers rather than a single thick application. This multi-coat approach requires additional production time but delivers a 35% improvement in edge durability when subjected to repetitive stress testing compared to single-coat applications of equivalent thickness.

Heat sealing is the ideal method for webbing edge treatment when manufacturing thermoplastic-coated materials including PVC, polyurethane, and nylon-coated webbing. Production efficiency metrics show heat sealing reduces edge finishing time by 78% compared to painting methods, processing edges at 4-6 inches per second with equipment operating temperatures between 300-450°F. This method delivers cost savings of approximately $0.12-0.18 per linear foot in high-volume manufacturing.

Synthetic webbing with coating thickness of 0.5-1.2mm responds optimally to heat sealing, creating a molecular bond that achieves edge strength ratings of 85-92% compared to the original material. Production operations benefit from the minimal equipment footprint (typically 2-3 square feet) and low power consumption (800-1200 watts), making this method particularly suitable for space-constrained manufacturing environments.

Material compatibility testing is essential for production implementation—polyester-based webbing requires lower temperature settings (300-350°F) to prevent core fiber damage, while polypropylene-coated products can withstand higher temperatures (375-425°F) resulting in stronger edge seals. Manufacturing efficiency relies on precise temperature control systems with ±5°F accuracy to ensure consistent edge quality across production batches.

Heat sealed edges demonstrate superior performance in abrasion resistance tests, maintaining edge integrity through 2,500+ abrasion cycles compared to 1,800 cycles for edge painted alternatives. This makes heat sealing particularly valuable for manufacturing webbing components used in high-friction industrial applications including conveyor systems, load securements, and high-traffic safety equipment where edge integrity directly impacts product longevity.

Additional coating preserves webbing edge integrity by applying a matching protective layer directly to cut edges, creating a seamless barrier that extends the original coating’s properties across the entire webbing surface. Manufacturing tests demonstrate this method maintains 96% water resistance at edges compared to untreated edges which show 65% reduction in water repellency. The coating penetrates between exposed fibers, preventing unraveling and extending product lifespan by 40-60%.

Production implementation requires precise material matching, with coating viscosity between 3,500-5,000 cPs providing optimal penetration while maintaining defined edge boundaries. Manufacturers typically use dip application for narrow webbing (under 2 inches) and precision spray systems for wider materials, achieving 0.2-0.3mm coating thickness at edges to match the main webbing surface.

This method excels in marine and outdoor equipment manufacturing where consistent waterproofing properties across the entire webbing component are critical for product performance and longevity.

Mechanical finishing is suitable for industrial webbing edges because it creates reinforced, high-strength edge structures capable of withstanding 500+ pounds of tensile force without degradation. This method increases edge durability by 75% through folding, stitching, or binding techniques that encapsulate exposed fibers. Manufacturing operations benefit from the process’s compatibility with automated production lines, processing up to 100 feet per minute with proper equipment setup.

Heavy-duty applications including lifting slings, cargo straps, and industrial belting require mechanical edge protection to maintain safety ratings under load stress. Testing shows mechanically finished edges withstand 3x more abrasion cycles than chemically treated alternatives, making this method essential for high-friction industrial environments.

Rubberizing gel should be chosen for waterproof webbing edge treatment because it creates a flexible waterproof seal with 100% moisture resistance while maintaining edge flexibility down to -20°F. Manufacturing tests confirm rubberized edges withstand 200% more flexing cycles before showing signs of cracking compared to heat-sealed alternatives. The treatment creates a matte, professional finish with precise color-matching capabilities for high-end product applications.

Production implementation requires applying 2-3 thin layers (0.2mm each) with 30-minute curing intervals between applications. The gel’s molecular structure bonds directly to both natural and synthetic fibers, creating cross-linked polymer chains that prevent water penetration while allowing the edge to flex with the webbing. Manufacturing facilities typically achieve optimal results using precision applicators with 0.5-0.8mm nozzle diameters for controlled application.

This method is particularly valuable for marine equipment manufacturing, outdoor gear production, and waterproof safety equipment where maintaining complete moisture resistance at cut edges directly impacts product performance and user safety.

Material properties affect edge treatment selection primarily through coating composition, fiber type, weave density, and temperature resistance. Polyurethane-coated webbing requires edge paints with 2.5-3.0 MPa adhesion strength, while silicone-coated materials are incompatible with heat sealing due to their 600°F+ melting point. Thermoplastic coatings like PVC and TPU respond optimally to heat sealing with 85-92% edge strength retention.

Fiber composition directly impacts treatment durability—aramid fibers require specialized high-temperature edge treatments formulated to withstand 400°F+ without degradation, while nylon-based webbing allows multiple treatment options due to its balanced thermal and chemical properties. Manufacturing operations must adjust processing parameters based on webbing density, with tight weaves (22+ picks per inch) requiring longer curing times for liquid treatments to properly penetrate between fibers.

Material thickness creates significant variation in treatment effectiveness—webbing exceeding 3mm thickness shows optimal results with mechanical finishing or multiple coating applications rather than single-pass treatments. Manufacturers should conduct material-specific testing, as chemical compatibility between coatings and edge treatments is essential for maintaining consistent product quality across production batches.

Testing the quality of coated webbing edge treatments requires standardized methods to ensure durability, adhesion, and weather resistance. Professional manufacturers rely on four key protocols: adhesion strength (ASTM D4541), abrasion resistance (ASTM D4157), environmental aging (ASTM G154), and edge seal integrity (ASTM D751).

Edge coatings must meet a minimum bond strength of 2.5 MPa using calibrated pull-off testers. Testing is performed 24 hours after coating application and repeated periodically during the first week of production. Samples below 2.0 MPa indicate insufficient surface preparation, improper primers, or coating incompatibility.

Edge-coated webbings are subjected to 2,000+ rub cycles under standard load conditions. Passing samples show no visible wear, cracking, or delamination, simulating long-term belt or strap use in high-friction conditions.

UV exposure testing at 340nm wavelength and 63°C for 500 hours simulates 1.5–2 years of outdoor exposure. High-quality edge treatments retain ≥85% of original adhesion strength. Treatments showing 40–60% degradation typically fail in real-world outdoor use.

Additional validations include thermal cycling from -20°F to +180°F with no cracking or peeling (ASTM D1204), salt spray resistance of 96+ hours without edge delamination (ASTM B117), and seal integrity confirmation using ASTM D751 to ensure coatings withstand water ingress and tensile stress at seams.

Manufacturers implement inline inspections every 50 feet of webbing to check edge uniformity. Coating thickness is measured using ultrasonic gauges with ±0.05mm tolerance, and periodic cross-sectional analysis confirms coating penetration and fiber bond quality.

✅ Recommendation: Choose suppliers with in-house testing or third-party validation to ensure edge treatment reliability. Proper quality control ensures real-world performance, reduces returns, and supports compliance for demanding applications like outdoor gear, vehicle restraints, or medical straps.

Selecting the appropriate edge treatment method for coated webbing depends on material properties, application requirements, and manufacturing capabilities. Understanding the strengths of each method—from edge painting to heat sealing, additional coating, mechanical finishing, and rubberizing gel application—enables manufacturers to deliver products with optimal edge performance for specific industry needs.

Heat sealing is only effective on thermoplastic-coated webbing such as PVC, TPU, and certain nylon coatings. Silicone-coated, rubber-coated, and certain specialty-coated webbings are incompatible with heat sealing due to their high melting points or non-thermoplastic properties. Always verify material compatibility before implementing heat sealing in production.

Proper edge treatment typically preserves 90-95% of original webbing strength while untreated edges can deteriorate to 65-70% strength after exposure to environmental factors. Mechanical finishing actually increases edge strength by 15-20% through reinforcement. Excessive heat treatments can reduce strength by damaging core fibers if temperature controls are inadequate.

Edge treatments vary in visibility—rubberizing gel and additional coating can be nearly invisible when color-matched to the webbing. Edge painting adds a visible border approximately 0.5-1mm wide. Heat sealing creates a subtle melted edge with minimal visual impact. Mechanical finishing is the most visible treatment, adding approximately 2-4mm to the edge profile.

Rubberizing gel application requires precision applicators with 0.5-0.8mm nozzle diameters, curing racks with proper ventilation, temperature-controlled drying stations, and proper personal protective equipment. Some manufacturers also utilize automated application systems with controlled pressure settings of 8-12 PSI for high-volume production.

Rubberizing gel provides the best waterproofing performance with 100% moisture resistance at treated edges. Additional coating methods deliver 96% water resistance when properly applied, while heat sealing offers 85-90% water resistance. Edge painting provides moderate waterproofing (70-80%) but requires multiple coats for optimal performance.

Edge paint on coated webbing typically requires 24-48 hours for complete curing. The first stage of drying occurs within 30-45 minutes, but full chemical bonding and maximum durability develop over 1-2 days. Temperature and humidity significantly impact curing time, with optimal conditions being 68-75°F and humidity below 55%.