As a custom webbing manufacturer, we frequently receive inquiries from product developers asking about 1.5-inch webbing specifications and optimal applications. This post addresses the most common design questions we encounter, helping you make informed material selections and avoid costly specification mistakes. Our manufacturing expertise enables us to provide tailor-made solutions that optimize your product’s performance requirements.

1.5-inch webbing is used in hammock suspensions, backpack straps, cargo tie-downs, pet collars, safety harnesses, and furniture support due to its balance of strength and flexibility. Depending on material—nylon, polyester, or polypropylene—it supports loads from 700 to 5,500 lbs, making it suitable for both recreational and industrial applications.

Explore specs, material options, and design tips for 1.5-inch webbing to optimize product performance and guide smart manufacturing decisions.

Webbing manufacturing expert with 15+ years of experience helping product developers build high-performance straps for industrial, medical, and outdoor use.

1.5-inch webbing load capacity ranges from 700 to 5,500 pounds breaking strength depending on material selection. Nylon webbing achieves the highest tensile strength at approximately 5,500 lbs, polyester webbing typically reaches 700-1,000 lbs, while polypropylene offers lighter-duty applications around 400-700 lbs breaking strength.

Key Load Specifications:

These values come from ASTM D5034 tensile testing under controlled conditions. Working load limits should never exceed 20% of breaking strength for safety-critical uses, or 33% for general applications. For example, nylon webbing with 5,500 lbs breaking strength translates to a maximum working load of 1,100-1,833 lbs.

From our manufacturing experience, customers often confuse breaking strength with safe working loads, leading to over-specification or dangerous under-specification. Load capacity directly impacts material cost—nylon’s superior strength justifies premium pricing for demanding applications.

Design Takeaway: Calculate your required working load first, then multiply by appropriate safety factor (3:1 minimum for safety applications, 5:1 for critical lifting) to determine minimum breaking strength specification.

1.5-inch webbing is primarily used for outdoor equipment, safety applications, furniture support, and apparel accessories. This width provides an optimal balance between strength and flexibility, making it suitable for hammock suspension systems, backpack straps, cargo tie-downs, pet collars, and camping gear applications.

Primary Application Categories:

The 1.5-inch width distributes weight more evenly than narrower options while remaining more manageable than wider alternatives. In hammock applications, this width minimizes tree damage while providing secure attachment points. For backpack straps, it offers comfortable load distribution without excessive bulk that interferes with shoulder movement.

From our manufacturing perspective, 1.5-inch webbing represents the sweet spot for many applications—wide enough for meaningful load distribution but narrow enough for versatile integration into various product designs. We’ve seen it successfully used in everything from pet leashes requiring gentle control to industrial cargo straps demanding reliable load securing.

Design Takeaway: Choose 1.5-inch webbing when you need moderate load distribution with design flexibility. Consider narrower widths for decorative applications or wider options for maximum load spreading requirements.

Nylon offers the highest strength, polyester provides superior weather resistance, and polypropylene delivers cost-effectiveness for 1.5-inch webbing applications. Material selection depends on environmental conditions, load requirements, and budget constraints rather than a single “best” option.

Material Performance Comparison:

Laboratory testing shows nylon absorbs up to 8% of its weight in water, potentially affecting dimensional stability under wet conditions. Polyester maintains >90% strength retention after 1,000 hours of UV exposure according to ASTM G155 weathering tests. Polypropylene costs 40-60% less than nylon but experiences rapid degradation under UV exposure without stabilizers.

From our material processing experience, polyester consistently demonstrates superior environmental stability, while nylon provides unmatched tensile performance in controlled conditions. REACH and OEKO-TEX® Standard 100 compliance is achievable across all three materials with proper sourcing and processing controls.

Design Takeaway: Specify polyester for environmental durability requirements, nylon for maximum strength specifications, and polypropylene for cost-sensitive projects where performance demands are moderate.

Yes, 1.5-inch webbing is safe for load-securing when specified according to DOT and OSHA regulatory requirements. Compliance requires proper safety factor calculations and material certifications for transportation and industrial securing applications.

Regulatory Safety Requirements:

DOT regulations mandate webbing systems withstand 0.5g forward, 0.5g rearward, and 0.2g lateral acceleration forces without failure. OSHA guidelines for industrial applications require similar conservative calculations with documented material certifications and regular inspection protocols.

From our regulatory compliance experience, load-securing failures typically result from inadequate documentation rather than material performance issues. Transportation authorities require traceable material certifications and compliance with federal motor carrier safety regulations for commercial cargo securing applications.

Design Takeaway: Ensure material suppliers provide DOT/OSHA compliance documentation, specify appropriate safety factors per regulatory requirements, and implement inspection schedules to maintain certification compliance throughout service life.

1.5-inch webbing limitations include temperature sensitivity, chemical incompatibility, and dimensional constraints for specific applications. Understanding these boundaries helps determine when alternative materials or widths provide better performance solutions.

Material Limitation Boundaries:

Nylon becomes brittle below -40°F while polypropylene maintains flexibility but suffers UV degradation without stabilizers. Chemical exposure to petroleum products, cleaning solvents, or industrial chemicals can cause rapid strength loss across all webbing types. Width constraints become apparent when contact area requirements exceed 1.5-inch capacity for pressure-sensitive applications.

From our technical consultation experience, customers often discover limitations after prototyping rather than during initial specification. Early identification of environmental conditions, chemical exposure risks, and dimensional requirements prevents costly design revisions and performance failures.

Design Takeaway: Evaluate operational temperature ranges, chemical exposure risks, and contact pressure requirements early in design process. When limitations are identified, consider treated materials, protective coatings, or alternative webbing widths to achieve performance targets.

Custom 1.5-inch webbing orders require quantity specifications, customization details, and lead time planning for manufacturing scheduling. Minimum order quantities start at 1,000 yards for standard customizations, with 2-4 week production timelines depending on complexity.

Custom Manufacturing Process:

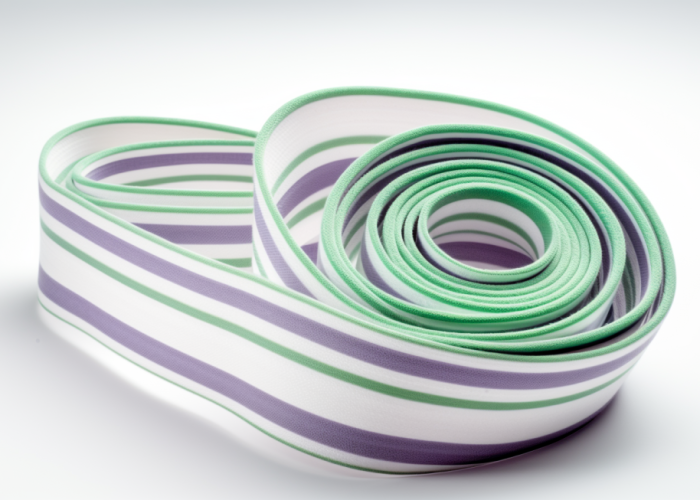

Available customizations include solution-dyed color matching, screen printing for logos and text, jacquard weaving for decorative patterns, and specialized surface treatments. Complex customizations like flame retardancy or antimicrobial treatments require extended lead times and higher minimum quantities.

From our custom production experience, successful projects follow a structured development process beginning with application consultation and sample approval. We provide manufacturing feasibility assessments to ensure custom specifications are achievable within budget and timeline constraints, often suggesting design modifications that improve manufacturability without compromising performance.

Our facility maintains ISO 9001 quality management certification and provides comprehensive documentation including material certificates, test reports, and compliance verification for customer quality assurance requirements.

Design Takeaway: Plan custom webbing orders 6-8 weeks before needed delivery dates, request samples early in the design process to verify specifications, and maintain open communication throughout development to ensure manufacturing success and on-time delivery.

1.5-inch webbing provides versatile load capacity from 400-5,500 lbs across multiple applications, with material selection determining environmental performance and cost-effectiveness. Polyester offers the best balance of strength and weather resistance for most product development needs. Contact us to explore manufacturing solutions tailored to your 1.5-inch webbing requirements.

Standard customizations start at 1,000 yards minimum. Complex treatments or specialty materials may require 3,000-5,000 yard minimums. We offer smaller prototype quantities (100-500 yards) for initial testing and design validation.

We provide tensile strength certificates, UV resistance testing, and material compliance documentation. Third-party testing available through accredited labs for customer verification. All materials include traceability documentation for quality assurance requirements.

Yes, 1.5-inch webbing fits standard hardware systems. We can recommend compatible buckles, adjusters, and attachment hardware, or work with your existing supplier specifications to ensure proper fit and function.

Yes, our engineering team provides application consultation, material recommendations, and design optimization suggestions. We help identify potential issues early and suggest improvements that enhance product performance while meeting cost targets.

Prototype samples: 1-2 weeks. Production orders: 2-4 weeks for standard customizations, 4-6 weeks for specialized treatments. Rush orders available with expedited scheduling for urgent project requirements.

Polypropylene costs 40-60% less than nylon, while polyester falls between them. Nylon’s premium price reflects superior strength, but polyester often provides better value for outdoor applications due to UV stability and longer service life.